Asphalt and Concrete Crack Routers (CR)

Crack Sealing and Waterproofing

Request A Qoute

Crack Sealing and Waterproofing

Request A Qoute

CR300KDC

586 lbs (266 kg)

|

Dust Collection

The Marathon Pavement Crack Router offers a more productive method of routing random cracks in asphalt. The balanced weight distribution, inline wheels and cutter head, plus extended handle, effectively reduces operator fatigue and allows for safer, smoother, and more accurate maneuverability.

*Custom Paint Colour

FEATURES

ADD ONS

LIST OF ADD-ON OPTIONS

01-1110

01-1100

01-1123

01-1130

01-1140

05-2053

01-1151

01-1076

01-1090

01-1016

01-7000

01-7301

01-7303

01-1280

Case Studies

6ixview Asphalt Services Case Study - CR300K

Location: Markham, Ontario, Canada

Equipment Used: KERA180BRE, CR300K

6ixview Asphalt Services Inc. is a thriving new asphalt repair service business based out of Markham, Ontario, Canada. They were recently tasked with routing and sealing some existing municipal asphalt cut-out road repairs in the Raymerville - Markville East neighborhood.

To perform a high-quality job, they chose to use two of their top-performing Marathon fleet machines, the CR300K asphalt crack router and the KERA180BRE hot rubber asphalt melting kettle.

This portion of a two-part case study will focus on the role of their CR300K asphalt crack router. Click to learn more about the "KERA180BRE crack-sealing kettle's role in municipal road structure preservation projects".

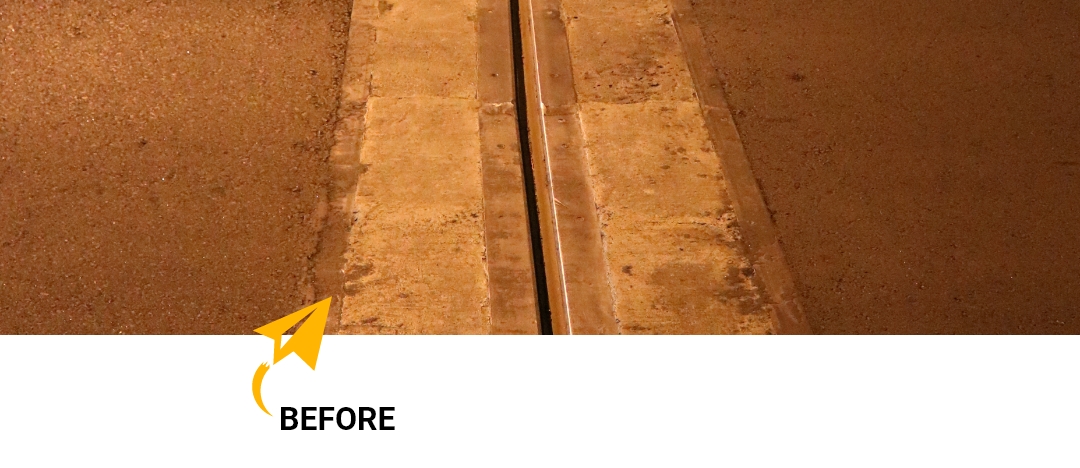

By way of background, smaller sections of asphalt in a roadway often become so degraded or damaged that they need to be cut out and replaced with new hot-mix asphalt in a process called "cut-out asphalt road repair". While it is economically beneficial to selectively patch a road before full replacement, this method also creates a seam where the old and new asphalt meet.

Unfortunately, this joint is not physically or chemically bonded (unless a proper amount of tack and compaction was applied during repairs) and will eventually allow water penetration to occur as it separates.

It is this moisture intrusion, along with a few freeze/thaw cycles, which causes the asphalt joints to deteriorate prematurely.

Therefore, it is necessary to seal such pavement joints with some kind of rubberized, waterproofing material.

However, before you can fill the irregular crack lines, asphalt repair contractors must first create clean, dry channels where the differently-aged asphalt meet. To widen the seams enough to allow sufficient crack sealant material to be injected / 6ixview Asphalt Services used their Marathon Equipment CR300K asphalt crack router which comes with a 12" diameter cutter head fabricated from 1" steel plate, equipped with six carbide tipped router blades strategically positioned on the router head. This configuration allowed the road repair contractors to adjust the blades in order to meet municipal government engineering specifications.

6ixview Asphalt believes that the CR300K asphalt crack router was essential for the rout & seal process used in this instance of pavement preservation in that it created a proper channel for the application of hot-melted crack-filling rubber.

Once the channel was routed and cleaned with a blower, Marathon Equipment's KERA180BRE was used to apply Maxwell Products Elastoflex 410 hot-melt crack-filling rubber at the channelized seams. This crack-sealing process created a waterproof barrier between the old and new asphalt road repair in order to extend the usable lifespan of that road section.

This pavement preservation process, which involved various rout and seal road repairs in multiple locations within the neighborhood, took approximately 4 hours from start to finish. If you would like to learn how to get more productively with an asphalt crack router, please contact our sales department.

Fine Line Markings Bridge Joint Repair

Location: Stoney Creek, Ontario, Canada

Equipment Used: KERA370BRE, CR300K, Hot Air Lance

Fine Line Markings, an experienced asphalt restoration contractor based out of Ontario, Canada, was tasked with a preventative maintenance project on a bridge deck. To ensure the cracks were properly prepared for sealing, they used the CR300K asphalt crack router.

The CR300K asphalt crack router was a critical component of the bridge deck maintenance project. By effectively cutting and preparing the cracks in the asphalt surface, the router created a more secure and stable base for the crack-sealing material to adhere to, resulting in a stronger and longer-lasting repair. The router"s efficient design and powerful engine enabled the customer to complete the job quickly and effectively, without causing damage to the surrounding areas.

The CR300K"s adjustable depth control and versatile routing heads allowed the customer to tailor the router to the specific needs of the job, ensuring that the cracks were properly prepared for sealing.

Water penetration leads to premature asphalt deterioration and expensive bridge joint road repairs which cost municipalities large sums of taxpayer dollars for having to fully repair and repave, not to mention road congestion and complaints from lane or bridge closures.

To create a watertight bridge joint — Fine Line Markings used the Marathon CR300K to create a clean uniform channel in which to place rubberized waterproofing compound. Marathon's CR300K came equipped with a 12" diameter cutter head made from 1" steel plate, equipped with six carbide tipped router blades which are strategically positioned on the router head.

Once in motion, the C300K dug into the asphalt flawlessly and was able to complete the job in a timely manner. Marathon"s router was able to create a uniform channel consistent with the depth and width needed to meet the job specifications.

To ensure the highest level of preparation and repair for the cracks on the bridge deck, Fine Line Markings used a combination of Marathon Equipment Inc. items, including the KERA370-BRE hot-rubber crack-sealing kettle and the hot air lance (HAL).

The KERA370-BRE kettle was used to effectively seal the cracks, while the HAL was used to remove debris and prepare the surface for sealing. For more information on the KERA370-BRE and HAL, please visit their respective product pages.

Each piece of equipment played a crucial role in ensuring that the cracks were properly sealed, the surface was adequately prepared, and debris was removed, all of which contributed to extending the lifespan of the bridge and improving its safety.