Hot Air Lance (HAL)

Crack Sealing and Waterproofing

Request A Qoute

Crack Sealing and Waterproofing

Request A Qoute

*Custom Paint Colour

Hot Air Lance

Portable

N/A

The Marathon Hot Air Lance is a high temperature, high velocity, hot air lance that will easily dry moisture from the pavement allowing the operator to crack seal much faster! This process is ideal for the preparation of crack sealing because it allows for superior adhesion of the crack sealant into the asphalt. This process extends the life of the repair for years to come!

FEATURES

ADD ONS

LIST OF ADD-ON OPTIONS

08-1153

15-3500

19-1001

19-1005

07-5000

Projects

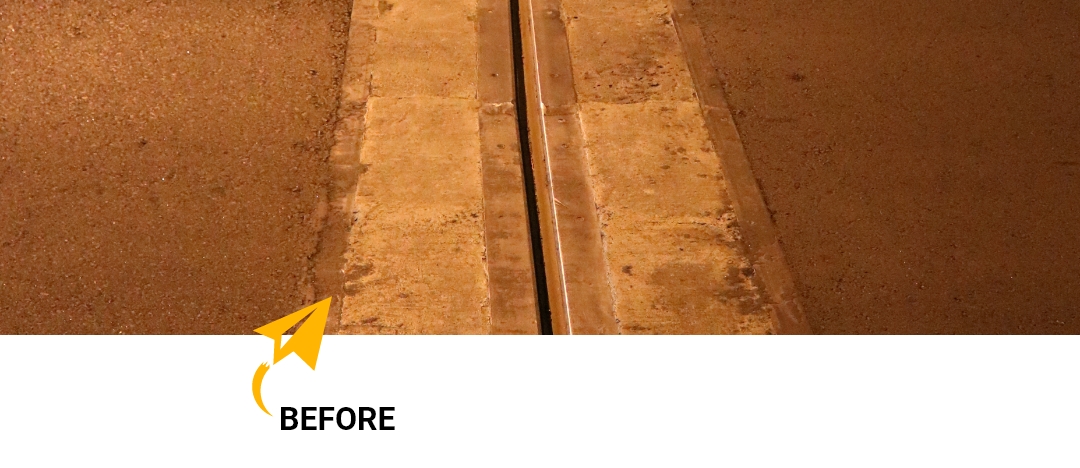

Fine Line Markings Bridge Joint Repair

Location: Stoney Creek, Ontario, Canada

Equipment Used: KERA370BRE, CR300K, Hot Air Lance

Fine Line Markings, a local asphalt servicing business based out of Ontario, Canada, was recently tasked with a bridge deck preventative maintenance project. To ensure the cracks were properly prepared for sealing, they used the hot air lance (HAL) from Marathon Equipment.

In this case study, we will examine how the HAL was able to help Fine Line Markings achieve a higher level of efficiency and effectiveness in preparing the surface of the bridge deck for crack-sealing.

The hot air lance (HAL) from Marathon Equipment Inc. was an essential tool for preparing the surface of the bridge deck for crack-sealing. By using a high-temperature stream of compressed air, the HAL effectively removed debris, moisture, and vegetation from the cracks, ensuring that the crack-sealing material would adhere properly.

Marathon's Hot Air Lance is powered by an 80 CFM Viper Compressor outputting 100 PSI of compressed air and a regulated propane flame. This allows the Marathon Hot Air Lance to output heat at consistent temperatures of up to 2500 Fahrenheit.

The HAL's lightweight and maneuverable design made it easy for the customer to access hard-to-reach areas of the bridge deck, ensuring that all cracks were properly prepared for sealing. Additionally, the HAL's adjustable temperature control and lance length allowed the customer to tailor the tool to the specific needs of the job, resulting in a more efficient and effective maintenance solution.

By using the HAL, the customer was able to ensure that the cracks were properly prepared for sealing, reducing the likelihood of further deterioration and extending the lifespan of the bridge deck.

Fine Line Markings used a variety of equipment items for their bridge deck preventative maintenance project, including the KERA370-BRE hot-rubber crack-sealing kettle and the CR300K asphalt crack router. The KERA370-BRE kettle was used to effectively seal the cracks, while the CR300K router was used to cut and prepare the cracks for sealing. For more information on the KERA370-BRE and CR300K, please visit their respective product pages.

In summary, the use of the KERA370-BRE hot-rubber crack-sealing kettle, CR300K asphalt crack router, hot air lance (HAL), and Billy Goat debris blower enabled Fine Line Markings to effectively execute their preventative maintenance project on the bridge deck.

These equipment items were able to seal cracks, prepare the surface, and remove debris, all of which contributed to extending the lifespan of the bridge and enhancing its safety. By utilizing these tools, Fine Line Markings was able to achieve a higher level of efficiency, productivity, and quality of workmanship.