Oil Jacketed Melting Kettles With Heated Hose And Wand (KERA)

Crack Sealing and Waterproofing

Request A Qoute

Crack Sealing and Waterproofing

Request A Qoute

KERA270BRE

270 Gallons

|

Trailer

Marathon's KERA models are designed for high production crack filling of hot poured rubberized crack sealants. These diesel fired kettles feature an electrically heated hose delivery system that is capable of heating, melting and applying rubberized crack sealant, not requiring any additional equipment!

*Custom Paint Colour

FEATURES

ADD ONS

LIST OF ADD-ON OPTIONS

21-5031

03-2305

03-0121

21-4010

17-0007

17-0001

09-7072

09-7048

21-5029

21-5005

21-5045

21-5037

21-1011

21-5039

21-5017

21-5001

21-5003

Case Studies

6ixview Asphalt Services Case Study - KERA180BRE

Location: Markham, Ontario, Canada

Equipment Used: KERA180BRE, CR300K

6ixview Asphalt Services Inc. is an up-and-coming but thriving asphalt service business based out of Markham, Ontario, Canada. They were recently tasked with routing and sealing the fresh asphalt cut out road repairs in the Raymerville - Markville East neighborhood.

To perform a high-quality job, 6ixview Asphalt Services chose two primary Marathon machines, the CR300K asphalt crack router and the KERA180BRE hot rubber asphalt melting kettle. This portion of the case study will focus on the role the KERA180BRE played. If you would like to learn more about the CR300K asphalt crack router. Please click here.

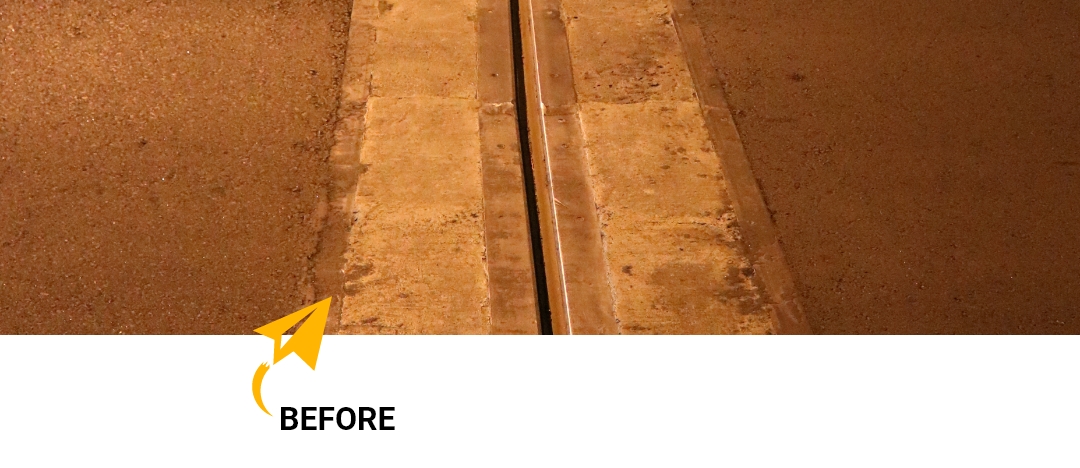

When damaged asphalt is cut out and replaced with new asphalt this method of road repair is called a "cut out asphalt road repair". This creates a seam where old and new asphalt meet. This seam is not waterproofed and allows for water penetration to occur, which causes the asphalt to become brittle and prematurely deteriorate.

To ensure that they were applying accurate amounts of hot rubber into the routed seam, 6ixview Asphalt Services decided to use a Marathon KERA180BRE crack sealing kettle.

The KERA180BRE crack sealing kettle is an important road repair tool in this process since it can melt Maxwell Products' Elastoflex 410 hot rubber crack filler in a short period of time and be able to apply it accurately through ergonomically designed wands. One block of Maxwell's Elastoflex 410 hot rubber crack filler was able to cover approximately 50 linear meters in this application.

Afterwards, a light coating of Glenzoil 20 Plus was sprayed over the freshly applied hot rubber crack filler. This allowed residential traffic to get moving without undue delay since it helps prevent material from being tracked by vehicles, provided you allow for a reasonable cooling period.

This method of pavement preservation saves cities money in road repairs by extending the life of existing asphalt for as long as possible before replacement is required.

This particular road repair took approximately 4 hours from start to finish and involved various rout and seal road repairs at multiple locations within the assigned neighborhood.

If you would like to learn how to get more productively out of your crack sealing kettle operations please contact our sales department.

Fine Line Markings Bridge Joint Repair

Location: Stoney Creek, Ontario, Canada

Equipment Used: KERA370BRE, CR300K, Hot Air Lance

Fine Line Markings, an asphalt repair and waterproofing business based out of Ontario, Canada, was recently tasked with a preventative maintenance project on a bridge deck.

To seal the cracks and prevent further deterioration, they relied on the KERA370-BRE hot-rubber crack-sealing kettle.

In this case study, we will examine how the KERA370-BRE kettle was able to help Fine Line Markings achieve a high level of workmanship and efficiency while preventing further damage to the bridge deck.

Marathon's KERA370-BRE hot-rubber crack-sealing kettle was instrumental in preventing further deterioration of the bridge deck by sealing cracks and preventing water infiltration. The kettle's high-quality heating elements and efficient insulation ensured that the crack-sealing material was heated and kept at the optimal temperature for a longer period, allowing for more effective application of the material.

The KERA370BRE crack sealing kettle melted the hot rubber crack filling material and dispensed it through the 22' foot electrically heated hose and ergonomically designed applicator wand with a 3" sealing swivel shoe. This allows for more precision when it comes to dispensing the rubber in the newly formed heated channel. The kettle's large capacity of 370 gallons ensured that the job could be completed without frequent interruptions for refilling, saving time and effort.

By using the KERA370-BRE, the customer was able to save time, reduce material waste, and achieve a higher quality of workmanship, all while preventing further deterioration of the bridge deck.

In addition to using the KERA370-BRE hot-rubber crack-sealing kettle, Fine Line Markings also utilized other Marathon equipment for their bridge deck preventative maintenance project.

A CR300K asphalt crack router was used to effectively cut and prepare the cracks in the asphalt surface before sealing, while the hot air lance (HAL) was used to remove debris, moisture, and vegetation from the cracks. For more information on the CR300K and HAL, please visit their respective product pages.

In conclusion, the use of the KERA370-BRE hot-rubber crack-sealing kettle, CR300K asphalt crack router, hot air lance (HAL), and Billy Goat debris blower were instrumental in completing the customer's preventative maintenance project on the bridge deck.